2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

2020/10/13

Recently, Shaanxi Tiancheng Aviation Materials Co., Ltd. (hereinafter referred to as “Tiancheng Aviation Materials”) broke through the production problem of large-sized cylinder forgings and successfully delivered a titanium alloy cylinder forging with a length of more than 8 meters and a net weight of more than 3000Kg for nuclear power. The titanium barrel adopts a brand-new process design, and the wall thickness is only 35mm. It is currently the largest high-strength thin-walled titanium alloy barrel forging in China.

High-strength thin-walled titanium alloy tube forgings

This cylinder forging is mainly used in a nuclear power project, which has extremely high requirements for product strength, density, heat and corrosion resistance, and because of its large size, how to solve the problem of large temperature difference in the overall forming process, low terminal temperature and uneven stress and strain distribution Maintaining uniform organization, performance and wall thickness before and after the barrel forging is a technical difficulty in the early stage of the project planning.

本项目核心成员共同讨论技术方案

方案设计初期,天成航材技术人员充分考虑客户要求及终端应用场景,对产品成形过程中的应力场、应变场、温度场等影响产品组织性能和冷热加工性能的关键参数进行分析,通过多次严密地计算讨论,最终确定了“开坯-两相区锻造-镦饼-冲孔-扩孔-芯轴拔长-平端面-内孔粗车-径向成型-热处理-理化检测”的总体工艺方案。

High and low tissue

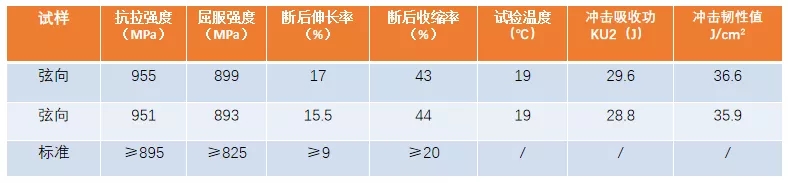

Organizational performance data

During the production process, Tiancheng Aviation Materials strictly follows the overall process plan and the GJB 943A-2018 quality standard, and is equipped with 4000T fast forging machines, 2000T radial forging presses and other international leading equipment to perform production tasks. The performance of the products meets customer requirements and meets the terminal Use standards.

“Focus on customer pressure and challenges, and continue to create customer value” has always been Tiancheng Aviation’s insistence. The successful delivery of the ultra-large high-strength titanium alloy tube forgings fully reflects Tiancheng’s work style of breaking through and courageously acting, and also inspires all Tiancheng to continue to overcome difficulties on the road to the development of the titanium industry and to cultivate advanced titanium alloys. The development and application of materials will strive to achieve more breakthroughs in the industry.