2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

2021/09/30

On September 30, it was the last day for the professionals in the 13th China International Aviation & Aerospace Exhibition (Short as Airshow China). As an upstream materials supplier of the aerospace supply chain, TC Aerospace received extensive attention from the academicians, experts, aircraft and components manufacturers and other related corporations. The titanium alloys one-stop solution provides more confidence and energy for the upgrading of the aerospace industry.

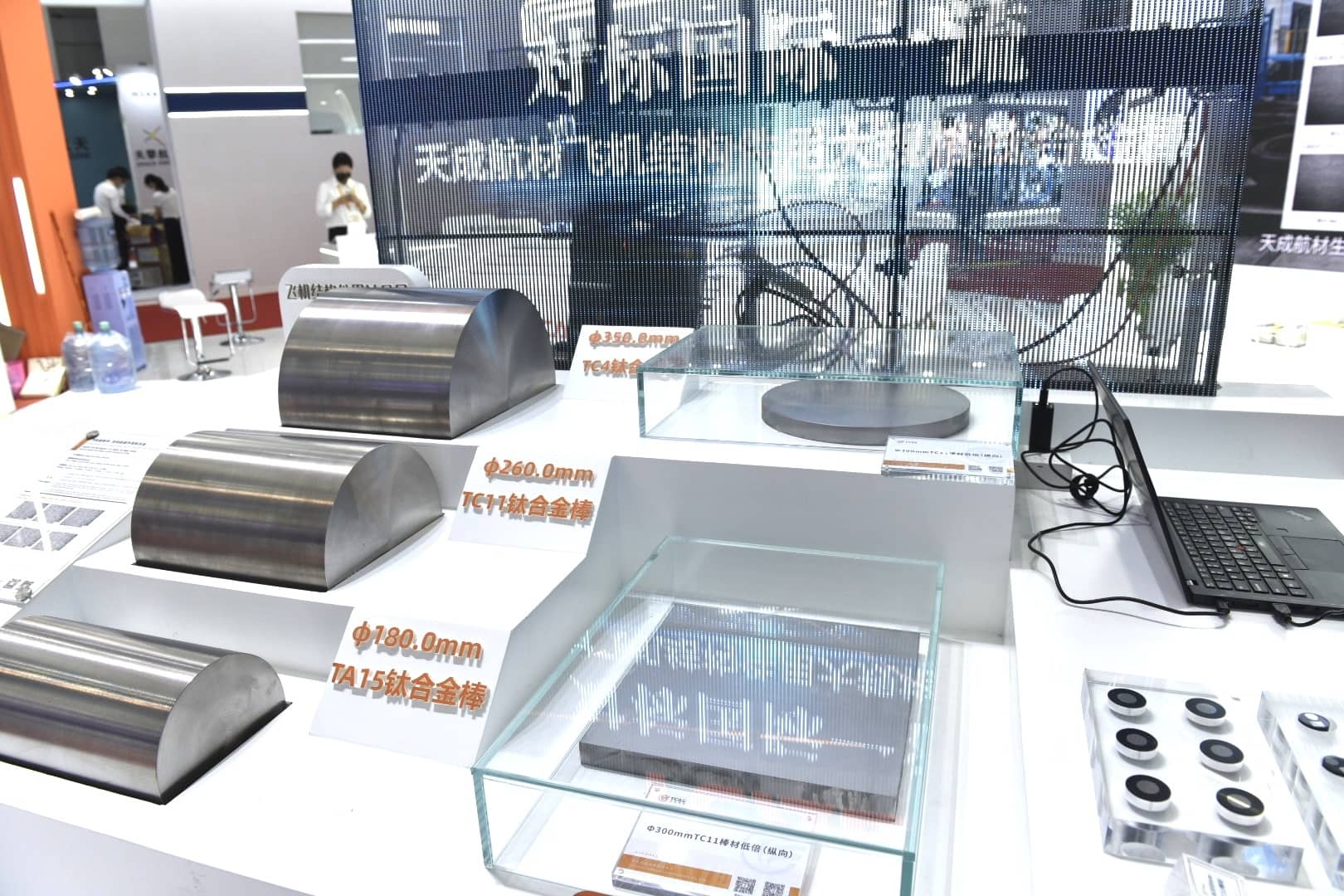

Stand of TC Aerospace

Stand of TC Aerospace

Advanced materials, enabling Aerospace market with strength

The stable supply of high-quality titanium alloys is the core technology related to national strategic security and reflecting the overall capability of national manufacturing technology. It is also the primary problem in the localization of titanium alloys for aerospace. Focusing on the demands of end users, TC Aerospace has carried out massive research on material genetic engineering to discover the potential of titanium alloys. The design, production and application of the material are closely combined to explore the core production process of titanium alloy suitable for the application of different aerospace components. Through “EBCHM + VAR” smelting, “forging and rolling combination” technology, whole process dynamic multi-directional temperature and speed control technology, these realized the high purity, high uniformity and high consistency production of titanium alloys of different specifications and applications, providing the core force for the upgrading of aerospace industry.

EBCHM + VAR Duplex Smelting Technology

Three Major Products to Solve the Urgent Needs of Aerospace Applications

Materials are one of the key problems affecting the development of aerospace industry. As a high-tech enterprise engaged in the research and production of basic materials, TC Aerospace has been committed to solving sore points of the consumers and creating new value with reliable products. The three major products participating in the Airshow China are produced with our core technology. The high-quality titanium alloy wire rod coils with a unit weight of more than 200kg can solve the problem of localization of aviation fastener materials; Ultrafine grain titanium alloy bars can greatly improve the strength and ductility, and improve the performance and service life of engine blades; The titanium alloys for aircraft structural parts are produced by the advanced process of “forging and rolling combination”, which can comprehensively improve the stability and performance of large-diameter bars.

High Quality Titanium Alloy Wire Rod Coil

High Quality Titanium Alloy Wire Rod Coil

Ultra-fine Grain Titanium Alloy Bars

Ultra-fine Grain Titanium Alloy Bars

Titanium Alloy for Aircraft Structural Parts

Titanium Alloy for Aircraft Structural Parts

High Popularity with Academicians and Experts Talking about “Stabilizing the Era”

By fully investigating the domestic and overseas markets and deeply analyzing the application demands, TC Aerospace forms a new development pattern that is leading domestic titanium alloys into a “stable era” and using advanced materials to develop aerospace market.

Based on the future demands of the aerospace industry, TC Aerospace intends to solve the technology gap of the basic material. It has written the material gene into the innovation and opened a new era of “titanium” 4.0 with advanced technology, making advanced materials made in China an inevitable choice for intelligent manufacturing in the future.